Professor Oren Tirosh

Professor Joseph Kanner

Eylon Asido, P.h.D student

| Category | FoodTech |

| Keywords | Lipid peroxidation; TBARS; Thermal treatment; Meat crust; Antioxidant |

| Current development stage | General list: TRL4 Technology validated in lab |

| Collaboration Opportunity | Licensing of Technology |

Abstract

The researchers found that when meat crust, produced in a unique manner, was added as a seasoning to consumer meat products, it functions as a semi natural antioxidant in preventing off-flavors associated with lipid oxidation.

Background

One of the main reasons for non-microbial meat product quality deterioration (taste and smell) is lipid peroxidation. Many different processing factors may affect the progression of lipid oxidation, such as handling, prolonged storage, heat treatments like cooking or heating etc. This process continues in the gastrointestinal tract after meat consumption following the absorption of advanced lipid peroxidation end products.

The global meat preservation market size was valued at USD 1.07 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 3.8% from 2021 to 2028. In recent years, there has been a growing demand for natural and clean-label meat products, leading to the development of new preservation methods that avoid the use of synthetic preservatives.

Our Innovation

The researchers found that the crust formed on the external layer of the fried meat using a unique production technique, functions as a semi-natural antioxidant that can protect against lipid peroxidation and extends shelf life of products that incorporate it.

- The researchers found a novel ingredient that significantly decreasing lipid peroxidation accumulation by utilizing fried meat crust.

- The production of this antioxidant crust is fast and cost effective.

- The crust can be easily added as grounded powder to various foods as seasoning.

Technology

The experiment was setup in two stages, the first to create the novel crust using the unique technique and the second to test the crust for its antioxidant properties in the membrane phase (MP), which is the lipid part of meat susceptible to oxidation (lipid peroxidation).

In the first stage, the outer crust from uniquely treated meat patties was isolated (crust), and the middle of the beef patties (MB) was also isolated as a control for the meat.

In the second stage, the membrane phase (MP) of ground meat from turkey and entrecote meat was extracted and tested in vitro either alone, with the addition of either Catechin (a known antioxidant), the crust (our novel antioxidant) or with the MB as control.

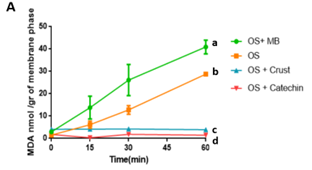

In the following graph we evaluate the antioxidant properties effect of the unique crust preservative. Lipid peroxidation accumulation was quantified by Thiobarbituric Acid Reactive Substances (TBARS) method, which utilizes Malondialdehyde (MDA) – a well-known lipid peroxidation indicator.

The graphs indicate that under the Oxidation System (OS) the crust acts as an antioxidant and additional results (not shown) indicate a dose dependent response.

Fig. 1. Evaluation of antioxidant properties of the Crust. MDA accumulation within 60 minutes with catechin, crust, and MB (A). Differences were considered significant at p 0.05 and indicated by different letters.

Opportunity

The researchers are looking for industry partners to sponsor further research so as to create a meat crust preservative seasoning that can extend the shelf life of food products that tend to have oxidation based off-flavors.